Sommerset Engineering has many years of experience with project implementation and has been involved in several large and small projects, where there has been a focus on Project Execution and Value Creation. Below are a number of key factors and value-creating observations for the various industries that we have worked with, as well as a selection of recent projects.

“The most important thing is patient safety above all, as the projects are most often carried out in areas where there are / may be patients who are ill and sick, and where the projects do not have to create extra strain."

- Focus Area:

Patient Safety, Reliability & Agility

Hospital Projects

“Product quality and on-time delivery have a strong focus in the pharma projects, where the documentation has great attention from both customers and authorities, so the products can live up to the requirements worldwide"

- Focus Area:

On-Time-Delivery,

Reliability & Agility

Pharma Projects

“These have been exciting projects with water supply, where the golden point has been that we must provide consumers with the best drinking water quality and thus a high level of customer satisfaction."

- Focus Area:

High level of safety, Operational stability & Long product lifespan

Water Supply Projects

“Oil & Gas projects have always been focused on the HSE - so hurry slowly so it is always safe to work and operate the plant!"

- Focus Area:

On-Quality-Delivery, Reliability & Longevity

Oil & Gas Projects

“Inspiring and exciting projects where the boundaries between infrastructure, urbanism and activism are broken down as innovators work with architects and planners or take activist approaches into use - hybrid projects."

- Focus Area:

Innovative, urbanism

& Flow Patterns

Infrastructure Projects

“Inspiring and exciting projects where the boundaries between reality and virtual simulation are broken down as innovators work with the simulators of the future in shipping, aviation and land-based systems."

- Focus area:

High-End Delivery, Reliability & Agility ”

Software & Simulation Projects

“ "

- Fokusområde:

On-Time-Delivery, Driftsikkerhed & Agilitet”

Energi Projekter

“ "

- Fokusområde:

On-Time-Delivery, Driftsikkerhed & Agilitet”

Marine Projekter

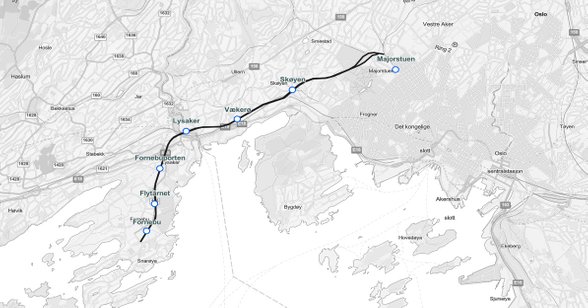

Expansion project to existing subway lines

Automation & HVAC Discipline Management:

Detail Engineering - The Fornebu line is a new metro line from Majorstuen to Fornebu. The track will be built in collaboration with Oslo Municipality and Viken County Municipality. The new metro development is the largest in Norway since the major extensions of the metro on the eastern outskirts of Oslo in the 1960s and 70s.

The new metro will, among other things, contribute to:

Oslo Kommune (NO) / PGF (NO)

Project period: 2022

Published: 5th of September 2022

Expansion project to existing water supply in Oslo

HVAC Discipline Management:

Detail Engineering - Oslo is Europe's fastest growing city, and forecasts indicate continued strong growth. In order to maintain quality and ensure the supply of drinking water, it is necessary to expand the supply capacity. The drinking water for Oslo's population is currently supplied with 90 percent from Maridalsvannet, but this supply solution can have serious consequences in the event of a failure in vital parts of the system, which supply the city with drinking water.

The supply capacity must therefore be increased and implemented with a redundant supply solution to ensure stable supply of drinking water and future population growth. The plant's capacity expansion is expected to be completed in the year 2028.

Water & Sewerage Authority "VAV", OsloMunicipality (NO)

Project period: 2021 - 2022

Published: 5th of September 2022

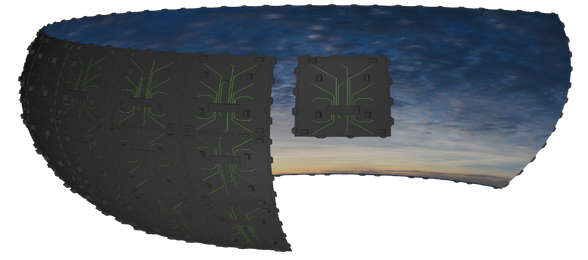

Display Systems & Simulation Applications

Project Management & Organizational Development:

Project Management - designs and delivers turn-key, seamless visual display systems and technologies for simulation applications. 3D Perception delivers turn-key systems with multi-projector display technologies allowing customers and their applications to accurately and automatically adjust images, automatically color calibrate and simplify maintenance with optimized solutions.

3D Perception (NO)

Project period: 2022

Published: 5th of September 2022

Life Extension Detail Engineering

Project Management & Multidiscipline Management:

Detail Engineering - Life extension, renovation and affiliation project. The life of the ship, Njord Bravo FSO, is extended from the original design life of 20 years to a total life of 40 years. The yard's scope of delivery is limited to renovation and construction. Brevik Engineering's role is to provide the complete technical basis for the yard's scope of delivery at the "detailed engineering level".

Equinor ASA (N) / Brevik Engineering AS (N)

Project period: 2019 - 2022

Published: 15th of January 2021

Project Management & Multidiscipline Management:

Detail Engineering - The project: Detail Engineering for Decommissioning of existing Building # 7 - "DECOM B7" (hereinafter referred to as "the project"), is a sub-project linked to the establishment of New Hospital Bispebjerg (hereinafter referred to as "BBH"), where the existing building # 7 (hereinafter referred to as "B7") must be demolished in stages to make room for New Hospital Bispebjerg.

The project thus results in the establishment of a report and description for the elements / systems in connection with. the demolition of B7. The report (s) are defined as a recommended “manual”, in which there is a robust basis for the service description in the forthcoming tender for the demolition of the North Wing for B7, as the first step in Decommissioning of B7.

B7 is shown in the middle of the bottom image.

Bispebjerg Hospital (DK) / LBP Engineering (DK)

Project period: 2018 - 2020

Published: 15th of January 2021

Expansion project - Neutralization & wastewater treatment plant

Project Management & Multidiscipline Management:

Detail Engineering - In connection with production expansion, AGC Biologics must have delivered a complete Kill & Neutralization plant, which must be established and integrated directly into existing plants and will function as a capacity expansion for both kill and neutralization processes.

GMO residues from production are decomposed in existing plants, which are expanded with additional buffer capacity for storage of peak loads. The buffer tank is connected as a connected vessel with the existing buffer tank.

Subsequent acid / base levels for production waste are neutralized (to pH 6.5-9) by adding acid / base from existing supply system. This happens in resp. existing and new neutralization tank.

AGC Biologics (DK) / LBP Engineering (DK)

Project period: 2018

Published: 15th of January 2021

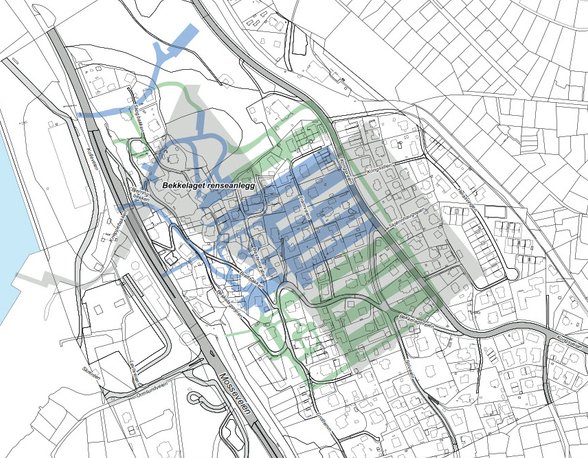

Expansion project UBRA (Development of Bekkelaget treatment plant)

Project Management & Multidiscipline Management:

Detail Engineering - Oslo is Europe's fastest growing city, and forecasts indicate continued strong growth. In order to maintain the quality of the water in the Oslo Fjord, it is necessary to expand the treatment capacity. The brook treatment plant purifies 40 percent of Oslo Municipality's wastewater. But it is congested and can not meet new environmental requirements. When the treatment plant was built in 2001 under the mountain, it was dimensioned for 270,000 people. The wastewater is now purified to 300,000 presons. The plant's capacity is increased to be able to handle wastewater from 500,000 people, which is the expected amount of wastewater for the year 2040.

PNC Norge (N) / NIRAS Norge (N)

Project period: 2017 - 2018

Published: 15th of January 2021

Expansion project - Process wastewater treatment plant

Project Management & Multidiscipline Management:

Detail Engineering - Novozymes, Denmark - Expansion of capacity in treatment plants for process treatment, biogas plants and gas power plants. Novozymes, the world leader in biological solutions, has launched an expansion program involving the construction of a new Biogas IC reactor plant with capacity for gas flow production up to 500 m3/h. The Biogas IC Reactor sub-project also includes a new and additional secondary clarification tank for increased operating capacity by more than 500,000 m3/year.

Novozymes (DK) / NIRAS (DK)

Project period: 2016 - 2018

Published: 15th of January 2021

Detail Engineering & Establishment - New European HQ

Project Management & Multidiscipline Management:

Detail Engineering - FMC Chemicals has in connection. further entry into the European market focused on a new European HQ, from which FMC Lab could establish laboratory facilities in a research environment such as SCION DTU, where in addition to office facilities, facilities for research in Nutritions, Enzymes and pesticides with fully equipped Green House for simulation of different scenarios for growth and plant conditions. The entire set-up was to be established in existing office facilities, which through thorough upgrades and conversions were to meet all laboratory facilities and expectations for these.

SCION DTU (DK) / NIRAS (DK)

Project period: 2016 - 2018

Published: 15th of January 2021